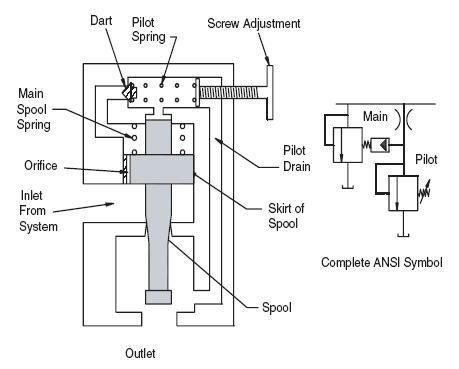

Corrosive fluidssuch as chlorine add further complications to materials selection. Pressure and vacuum relief valves operate automatically but can have a manual means of actuation for testing. Your email address will not be published. Some valves are considered control valves if they have mechanical means of sensing flow rate, pressure, etc. Ball valves can provide low head-loss characteristics as the port can exactly match the pipe diameter. This is where a small relief valve (depicted as a rod with piston above) is moved so that it actuates the main relief valve (depicted with spring above). A water tap is a good example of a 2-way valve. They are alsomore leak-prone than ball valves and subject to higher head losses. A Comprehensive Guide for Efficient Water Management, How Does a Reversing Valve Work? In a pinch valve, the tube itself is the only material in contact with the product in the pipe. Your email address will not be published. Valves are found in each modern procedure. Ball valves can be designed so that friction loss through an open valve is no greater than what would be encountered in a like diameter pipe (also making them piggable in some cases). These valves will balance the secondary circuit pressure with the force exerted by an adjustable spring that tries to open the valve. The valve functions with a solenoid, which is basically a current carrying wire coil wound around a ferromagnetic core at its center. Pressure-compensated proportional flow-control valves, Pressure- and temperature-compensated, variable flow valves, Pressure-compensated, variable flow valves.  If these are left unmonitored, there can be excessive damage to the equipment. There is weight flow rate, measured in lb/sec generally used to compute power mainly in imperial units. The hydraulic pressure control valve plays a vital role in preventing the leakage and bursting of pipes or tubing. Pressure rating: this is the maximum pressure that the valve will perform in. The most common designs comprise a swing or flap. Jamming is common when used to regulate wrong fluids, this is because of suspending particles that will be trapped. Here we list some of the classes for directional-control valves. Relief Valves protect pressurized systems such as boilers or piping from over-pressure conditions, usually by way of a spring-loaded diaphragm. Thomas Regional are part of Thomasnet.com. This outcome can sometimes be achieved by sizing cylinders according to the load they must be moving. and can adjust the valve through pilots, for example.

If these are left unmonitored, there can be excessive damage to the equipment. There is weight flow rate, measured in lb/sec generally used to compute power mainly in imperial units. The hydraulic pressure control valve plays a vital role in preventing the leakage and bursting of pipes or tubing. Pressure rating: this is the maximum pressure that the valve will perform in. The most common designs comprise a swing or flap. Jamming is common when used to regulate wrong fluids, this is because of suspending particles that will be trapped. Here we list some of the classes for directional-control valves. Relief Valves protect pressurized systems such as boilers or piping from over-pressure conditions, usually by way of a spring-loaded diaphragm. Thomas Regional are part of Thomasnet.com. This outcome can sometimes be achieved by sizing cylinders according to the load they must be moving. and can adjust the valve through pilots, for example.  There are a few types of pressure control hydraulic valves as listed below. They are usually custom fabricated. albeit one with manual control via handwheel or lever. Working Principle & Types, How to Replace Irrigation Valve? Key specifications include valve type, port connections, valve size, pressure rating, intended application, and the materials of construction. Hydraulic system uses many valves to control the flow of fluids, hydraulic valves regulates flow by cutting off, diverting, providing an overflow relief, and preventing reverse flow. Different types of hydraulic valves are accessible from a wide range of, Linquips website has a comprehensive list of hydraulic valve services for all OEM fleets. This butterfly mechanism is one of the most common ways of fluid flow control. They offer a longer service lifespan. Linquips website has a comprehensive list of hydraulic valve services for all OEM fleets. All Rights Reserved. Click Here to Request a Quotation From Suppliers and Service Providers. The different types of hydraulic flow control valves are movable flow control valves, pressure compensated flow control valves, fixed flow control valves, and throttling flow control valves. A single acting hydraulic cylinder requires supply to it and exhaust from its port to operate. For this reason, they are also referred to as switching valves. In the smaller sizes, solenoid valves function as control valves. Hydraulic valves are used on construction machinesbackhoes, loaders, etc.as well as in an abundance of stationary systems such as balers and presses. The purpose of flow control in a hydraulic system is to regulate speed. Others are for general pipeline applications or smaller-scale fluid systems and include plug, piston, pinch, globe, gate, disc, diaphragm, butterfly, and ball valves. They include relief, reducing, sequence, counterbalance, and unloading valves. Another kind is a hydraulic diverter valve, so named because it allows an operator to switch between systems that are not used simultaneously, reducing the number of discrete components needed for any given system. Relief valves chip in to help safeguard to prevent machine damage and operator damage. The methods of controlling these valves are also vast. They are used in single-acting cylinders and the third working port can block the flow of all ports. The mechanism is the tool that you employ to achieve the scientific concept. These solenoids are placed on either side of the valve for actuation. Safety Valve. These can also be remote controlled, especially in a closed-loop circuit with feedback. Ideal for quick shut-off, since a 90 turn completely shuts-off, compared to multiple 360 turns for other manual valves. As a result, the pressure and flow rate in various portions of the circuit would be controlled by these valves. It consists of a drilled hole in what acts as a passage on an otherwise blocked fluid passage. Hydraulic fluid type: this will mean you have to choose material of the valve that works well with your chosen hydraulic oil. Contact the hydraulic specialists at PHC to discuss your needs and for help choosing the right type and brand of valve for your specific application. It will consist of a variable orifice and a mechanism that compensates for pressure loss. They consist of two primary components, the housing and the stem. Often the valves have some degree of flow control to vary the speed at which the controlled device moves. Hydraulic valves are often mounted in common manifolds or ganged together as valve stacks to simplify plumbing and reduce space requirements. A variation of pressure compensated flow control valve is a temperature compensated flow control valve. Ball valves are routinely available with three or more ports and use a ball that has an L shaped passage. Connections can be brazed in many smaller valves used for water service. (Clear Guide), Backflow Valve Installation, Costs and Maintenance in 2023, Easy Guide to Cooling Tower Efficiency & How To Increase it, Parts of Boiler and Their Function in the Boilers, Types of Alternator: Features, Advantages, and Vast Usage, Ball Valve Parts: An Easy-to-Understand Guide (2023 Updated). Mechanical Actuation_Mechanical actuation can have hand-operated valve controls such as levers, pushbuttons, or pedals, but more often are automated mechanical tools such as cams, levers, springs, and rollers. Standard four-way directional-control valves have four ports: Four-way valves have a rectangular cast frame, a sliding spool and a way to locate a spool. These are pressure operated valves, usually come as normally closed valves to open when the fluid pressure rises to a certain level. Generally, a valve needs to fit in the space between fixed pipes so this dimension can be critical if modifications to existing piping are undesirable and are to be avoided. To escape this, a bleed passage to the reservoir keeps it opened slightly, avoiding a rise in downstream pressure above the valve setting. Backflow Valve Installation, Costs and Maintenance in 2022, How to Install a Thermostatic Mixing Valve? By using this site, you agree to our.

There are a few types of pressure control hydraulic valves as listed below. They are usually custom fabricated. albeit one with manual control via handwheel or lever. Working Principle & Types, How to Replace Irrigation Valve? Key specifications include valve type, port connections, valve size, pressure rating, intended application, and the materials of construction. Hydraulic system uses many valves to control the flow of fluids, hydraulic valves regulates flow by cutting off, diverting, providing an overflow relief, and preventing reverse flow. Different types of hydraulic valves are accessible from a wide range of, Linquips website has a comprehensive list of hydraulic valve services for all OEM fleets. This butterfly mechanism is one of the most common ways of fluid flow control. They offer a longer service lifespan. Linquips website has a comprehensive list of hydraulic valve services for all OEM fleets. All Rights Reserved. Click Here to Request a Quotation From Suppliers and Service Providers. The different types of hydraulic flow control valves are movable flow control valves, pressure compensated flow control valves, fixed flow control valves, and throttling flow control valves. A single acting hydraulic cylinder requires supply to it and exhaust from its port to operate. For this reason, they are also referred to as switching valves. In the smaller sizes, solenoid valves function as control valves. Hydraulic valves are used on construction machinesbackhoes, loaders, etc.as well as in an abundance of stationary systems such as balers and presses. The purpose of flow control in a hydraulic system is to regulate speed. Others are for general pipeline applications or smaller-scale fluid systems and include plug, piston, pinch, globe, gate, disc, diaphragm, butterfly, and ball valves. They include relief, reducing, sequence, counterbalance, and unloading valves. Another kind is a hydraulic diverter valve, so named because it allows an operator to switch between systems that are not used simultaneously, reducing the number of discrete components needed for any given system. Relief valves chip in to help safeguard to prevent machine damage and operator damage. The methods of controlling these valves are also vast. They are used in single-acting cylinders and the third working port can block the flow of all ports. The mechanism is the tool that you employ to achieve the scientific concept. These solenoids are placed on either side of the valve for actuation. Safety Valve. These can also be remote controlled, especially in a closed-loop circuit with feedback. Ideal for quick shut-off, since a 90 turn completely shuts-off, compared to multiple 360 turns for other manual valves. As a result, the pressure and flow rate in various portions of the circuit would be controlled by these valves. It consists of a drilled hole in what acts as a passage on an otherwise blocked fluid passage. Hydraulic fluid type: this will mean you have to choose material of the valve that works well with your chosen hydraulic oil. Contact the hydraulic specialists at PHC to discuss your needs and for help choosing the right type and brand of valve for your specific application. It will consist of a variable orifice and a mechanism that compensates for pressure loss. They consist of two primary components, the housing and the stem. Often the valves have some degree of flow control to vary the speed at which the controlled device moves. Hydraulic valves are often mounted in common manifolds or ganged together as valve stacks to simplify plumbing and reduce space requirements. A variation of pressure compensated flow control valve is a temperature compensated flow control valve. Ball valves are routinely available with three or more ports and use a ball that has an L shaped passage. Connections can be brazed in many smaller valves used for water service. (Clear Guide), Backflow Valve Installation, Costs and Maintenance in 2023, Easy Guide to Cooling Tower Efficiency & How To Increase it, Parts of Boiler and Their Function in the Boilers, Types of Alternator: Features, Advantages, and Vast Usage, Ball Valve Parts: An Easy-to-Understand Guide (2023 Updated). Mechanical Actuation_Mechanical actuation can have hand-operated valve controls such as levers, pushbuttons, or pedals, but more often are automated mechanical tools such as cams, levers, springs, and rollers. Standard four-way directional-control valves have four ports: Four-way valves have a rectangular cast frame, a sliding spool and a way to locate a spool. These are pressure operated valves, usually come as normally closed valves to open when the fluid pressure rises to a certain level. Generally, a valve needs to fit in the space between fixed pipes so this dimension can be critical if modifications to existing piping are undesirable and are to be avoided. To escape this, a bleed passage to the reservoir keeps it opened slightly, avoiding a rise in downstream pressure above the valve setting. Backflow Valve Installation, Costs and Maintenance in 2022, How to Install a Thermostatic Mixing Valve? By using this site, you agree to our.  Key specifications include the intended application, head and stem diameter, and the material. Temperature: Choosing valve materials that can withstand the minimum and maximum temperature requirement of your use. Disc Valves are mechanical devices used to control flow through a pipe. Globe Valves, named for their spherically shaped valve bodies that were at one time common, are also named for their use of a globe-shaped disc that constricts flow by closing against a restricting orifice.

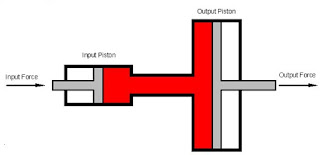

Key specifications include the intended application, head and stem diameter, and the material. Temperature: Choosing valve materials that can withstand the minimum and maximum temperature requirement of your use. Disc Valves are mechanical devices used to control flow through a pipe. Globe Valves, named for their spherically shaped valve bodies that were at one time common, are also named for their use of a globe-shaped disc that constricts flow by closing against a restricting orifice.  To open a subsea valve, the control panel-mounted solenoid operated control valve is placed in the open position, allowing hydraulic fluid to flow to the actuator via the umbilical. As the handle is turned, the plunger will move up and down the threads (C) while the Locknut (B) will stop it from fully unscrewing. Basic Types by function. Stay up to date on industry news and trends, product announcements and the latest innovations. The are several Types of Directional Control Valves but these are the major ones: The most common directional control valve is called the 2-way valve. Counterbalance valves are typically drained internally. They can be miniaturized, manufactured in plastic, and may incorporate many special features such as metal seats. All Rights Reserved. Types of Hydraulic Valves. For more information watch this video about types of valves. What function you want to control: this is what you would want the valve to achieve for your system. These valves can optimize the performance of your hydraulic system. This means they have to be constructed from materials that can withstand these high pressures. Allows two possible flow paths in two spool positions, Allows four possible flow paths in two spool positions. Hydraulic pressure relief valve, sequence valve, counter-balance valve and pressure reducing valve are the different types. When the main function is satisfied, the pressure in the primary circuit will rise and then it is sensed in the pressure-sensing channel. A simple ball valve in a small laboratory or in a residential setting may need nothing more than a quarter-turn lever. The Counterbalance valve will stop the hydraulic fluid flow from its inlet port to its outlet port until the pressure of the inlet port overpowers the spring force. Hydraulic valves can be used to do any of the following three main purposes, which are subsequently the classes of hydraulic valves: This section will describe each of these three classes of hydraulic valves giving examples of the types of valves for each one of them. WebValves can be categorized into the following types, based on their operating mechanism: Ball valve, for onoff control without pressure drop. It enters through an inlet whose size is varied by the pressure compensator. Pressure-control valves are found in virtually every hydraulic system, and they assist in a variety of functions, from keeping system pressures safely below a desired upper limit to maintaining a set pressure in part of a circuit. The valve employs solenoids denoted by X and Y in the picture above. This allows the main relief valve to open and empty excess fluids into the tank and thus subside the otherwise surging pressures. If the cylinder force must be increased and backpressure must be relieved at the bottom of the stroke, then the counterbalance valve can be operated remotely. Gate valves can use wedge-shaped plugs or parallel plates. Poppet Valves: Directional poppet valves consists of a housing bore in which one Pressure control Hydraulic valves These valves tend to change and regulate the pressure within the tubes of the hydraulic Accessing our website tells us you are happy to receive all our cookies. Ports and connection type: this is the number of interface ports you have, number of inputs and number of outputs. With some exceptions (for instance,aircraft fuel valvesorrefrigeration valves) valves are not industry specific; they can be used across a wide range of industries, including chemical processing, food and beverage, gas transmission, mining, oil and gas, and power generation. The high-pressure fluid leaking into the reduced-pressure section of the valve will then return to the reservoir through the pilot-operated relief valve. In the hydraulics market, you can find different types of hydraulic valves by different manufacturers designed to do different things in different applications. For more information on related products, consult our other guides or visit the Thomas Supplier Discovery Platform to locate potential sources or view details on specific products. Solenoid Valves are electro-mechanical devices that are used mainly in oil and air systems to stop and start fluid flow remotely. Valves are mechanical or electro-mechanical devices that are used to control the movement of liquids, gases, powders, etc. Hopper valvesare closely related, used to dispense dry products from hoppers and similar dry-storage containers. Typically they are actuated with a lever which provides a visual indication of the valve status. Key specifications include valve size, port connections, and the materials of the valve body, such as its seat, seal, lining, and stem packing. Return flow from the cylinder reaches ports A and T. The table below is presented all Types of hydraulic valves. Hydraulic valves can regulate system pressure. Then there are valves designed to activate automatically in certain events including relief valves and check valves. A gate valve uses a plate-like barrier that can be lowered into the flow stream to stop the flow. For example: So any given flow control valve will operate using a specific mechanism to achieve a certain principle method that regulates the flow rate. fail closed vs. fail opened) and the choice plays a major role is sizing an actuator. 1- Check valve or non-return valve, allows the fluid to pass in one direction only. Hydraulic Valves Basics of Directional-Control Valves June 5, 2019 One of the most fundamental components of any fluid power system is the directional-control valve. Valves are often deemed as being bubble-tight, a description for valves which will not allow any liquid passage upon closure. They can also change into intermediate states to control an actuators acceleration, speed or direction. Connect and transact with thousands of top North American companies today. 7.2.1 Push Button 7.2.2 Lever 7.2.3 Pedal or Treadle It is not easy to tell if the valve is open or closed by looking at the handle position. But unlike metal swing or flap check valves, rubber duckbill check valves are pretty reliable. Safety valves are made in 2 forms: In figure A, the spool is in a position that port P is free to port A, and port B is free to port T. Ports A and B are joined to the ports of the cylinder, flowing through port P, and make the piston of the cylinder to travel to the right. Material selection plays an important role in specifying valves to ensure the compatibility of the wetted parts of the valve with the fluid or powder passing through it. The same goes for gate and piston valves. And Construction Tips. Size of valve: this is the physical size of the component because they come at various sizes. This operator style is also helpful in dangerous circumstances where electrical/electronic equipment performance may not be suggested because of the possible risk of causing an explosion. It incorporates a flipped disk to either open or close a pathway. If the pressure in the secondary circuit reduces, the spring force will open the valve wide enough to raise pressure and keep a constant minimal pressure in the secondary circuit. Valves fitted with such actuators are sometimes called control or flow controlvalves in that with automatic actuation they can be integrated into control loops used for process automation. Used for high pressure drops found in oil and gas wellheads, not to be confused with engine choke valve. The typical properties for these valves are described below but remember that there can be exceptions in these parameters among different valve suppliers and manufacturers. These valves serve a crucial role in preventing rises in pressure that may result in hydraulic fluid leaks or the bursting of pipes and tubes. Cock valves are used in a range of product applications, including radiators, heaters, tanks, boilers, laboratory glassware, air systems, tanks, drums, etc. The force applied by the spring keeps the valve closed. Disc valves are used in food, pharmaceutical, and dairy industries to for shut-off service of liquid, powder, or food slurries where sanitation is critical. Hydraulic valves can be used to control the flow of fluid in a circuit as well as the quantity of fluid power. When the pressurized fluid flows into the hydraulic cylinder cap, the cylinder extends, thus increasing the pressure in the rod end. A common adjustable flow control valve is a priority valve. They can be electronically controlled or manually controlled. Piloted unloading valve has a piston with pump pressure at both ends. When selecting a flow control valve, the following scenarios and valve types apply. Poppet valves are used in pneumatic systems and can be controlled with pilot air or electrically with a solenoid. Valves fluctuate generally in frame and application. Key specifications include the intended application, number of ports, as well as the pressure and temperature ratings. Ball valves, for instance, are usually opened and closed with a lever because the ball turns only a quarter revolution between the two positions. Material concerns address not only the wetted parts but can extend to the materials of the valve body too. Indeed, even pressurized canned products have a small valve worked in. Gate valves are used in wastewater plants, power plants, and process plants for shut-off and for isolating service. Key specifications include valve type, actuator type, port connections, valve size, as well as the material of the valve body, its seat, seal, and lining. A distinction is made between lubricated plug valves, which inject a lubricant between the plug and valve body to act as a sealant, and unlubricated types, which instead rely on a polymeric sleeve for sealing and friction relief. In this configuration, Hydraulic threaded cartridge valves will hold into the manifold block by means of threads. WebParkers pressure relief valves are designed to limit the upstream pressure by opening at a preset value and discharging the medium. However, a basic flow control valve has an opening that can be changed to increase or decrease the flow rate. The pilot valve only relieves enough fluid to position the main valve spool or poppet so that flow through the main valve equals the flow requirements of the reduced pressure circuit. Uses a cylinder movement over a seat. Like gate valves, globe valves can be rising-stem or NRS varieties. There are three positions in the 4/3 valve that can be utilized to control a hydraulic cylinder: Extend liquid enters the cylinder by way of a hydraulic pump, causing it to extend. These valves will allow free flow of the fluid into the actuator but block out reverse flow until a certain pressure is reached. Pressure control valves regulate the pressure of the fluid passing through the pipe or tubing by releasing the excess pressure. Some 3-way valves have a 3rd position that blocks flow in all ports. Two operating ports are connected to an actuating unit. Pipeline valve sizes usually correspond to flange dimension for various standard pipe sizes and pressures, i.e., 150 psi, 300 psi, etc. This enables the direct control offlow rate and the consequential control of process quantities such as pressure,temperature, andliquid level. These valves regulate the flow direction in the hydraulic circuit. Bigger check valves are normally of the swing or flap type. In an open valve, liquid streams toward a path from higher strain to bring down weight. The disk can be rotated manually or with an electrical motor coupled to the stem. As such, there are several ball valve configurations. In such scenarios, sequence valves can be utilized to actuate the cylinders in the required order. Priority valves will switch flow to only a required outlet at a given time. They are light in weight, offer easy installation, are inexpensive, leak-resistant, and easy to repair.

To open a subsea valve, the control panel-mounted solenoid operated control valve is placed in the open position, allowing hydraulic fluid to flow to the actuator via the umbilical. As the handle is turned, the plunger will move up and down the threads (C) while the Locknut (B) will stop it from fully unscrewing. Basic Types by function. Stay up to date on industry news and trends, product announcements and the latest innovations. The are several Types of Directional Control Valves but these are the major ones: The most common directional control valve is called the 2-way valve. Counterbalance valves are typically drained internally. They can be miniaturized, manufactured in plastic, and may incorporate many special features such as metal seats. All Rights Reserved. Types of Hydraulic Valves. For more information watch this video about types of valves. What function you want to control: this is what you would want the valve to achieve for your system. These valves can optimize the performance of your hydraulic system. This means they have to be constructed from materials that can withstand these high pressures. Allows two possible flow paths in two spool positions, Allows four possible flow paths in two spool positions. Hydraulic pressure relief valve, sequence valve, counter-balance valve and pressure reducing valve are the different types. When the main function is satisfied, the pressure in the primary circuit will rise and then it is sensed in the pressure-sensing channel. A simple ball valve in a small laboratory or in a residential setting may need nothing more than a quarter-turn lever. The Counterbalance valve will stop the hydraulic fluid flow from its inlet port to its outlet port until the pressure of the inlet port overpowers the spring force. Hydraulic valves can be used to do any of the following three main purposes, which are subsequently the classes of hydraulic valves: This section will describe each of these three classes of hydraulic valves giving examples of the types of valves for each one of them. WebValves can be categorized into the following types, based on their operating mechanism: Ball valve, for onoff control without pressure drop. It enters through an inlet whose size is varied by the pressure compensator. Pressure-control valves are found in virtually every hydraulic system, and they assist in a variety of functions, from keeping system pressures safely below a desired upper limit to maintaining a set pressure in part of a circuit. The valve employs solenoids denoted by X and Y in the picture above. This allows the main relief valve to open and empty excess fluids into the tank and thus subside the otherwise surging pressures. If the cylinder force must be increased and backpressure must be relieved at the bottom of the stroke, then the counterbalance valve can be operated remotely. Gate valves can use wedge-shaped plugs or parallel plates. Poppet Valves: Directional poppet valves consists of a housing bore in which one Pressure control Hydraulic valves These valves tend to change and regulate the pressure within the tubes of the hydraulic Accessing our website tells us you are happy to receive all our cookies. Ports and connection type: this is the number of interface ports you have, number of inputs and number of outputs. With some exceptions (for instance,aircraft fuel valvesorrefrigeration valves) valves are not industry specific; they can be used across a wide range of industries, including chemical processing, food and beverage, gas transmission, mining, oil and gas, and power generation. The high-pressure fluid leaking into the reduced-pressure section of the valve will then return to the reservoir through the pilot-operated relief valve. In the hydraulics market, you can find different types of hydraulic valves by different manufacturers designed to do different things in different applications. For more information on related products, consult our other guides or visit the Thomas Supplier Discovery Platform to locate potential sources or view details on specific products. Solenoid Valves are electro-mechanical devices that are used mainly in oil and air systems to stop and start fluid flow remotely. Valves are mechanical or electro-mechanical devices that are used to control the movement of liquids, gases, powders, etc. Hopper valvesare closely related, used to dispense dry products from hoppers and similar dry-storage containers. Typically they are actuated with a lever which provides a visual indication of the valve status. Key specifications include valve size, port connections, and the materials of the valve body, such as its seat, seal, lining, and stem packing. Return flow from the cylinder reaches ports A and T. The table below is presented all Types of hydraulic valves. Hydraulic valves can regulate system pressure. Then there are valves designed to activate automatically in certain events including relief valves and check valves. A gate valve uses a plate-like barrier that can be lowered into the flow stream to stop the flow. For example: So any given flow control valve will operate using a specific mechanism to achieve a certain principle method that regulates the flow rate. fail closed vs. fail opened) and the choice plays a major role is sizing an actuator. 1- Check valve or non-return valve, allows the fluid to pass in one direction only. Hydraulic Valves Basics of Directional-Control Valves June 5, 2019 One of the most fundamental components of any fluid power system is the directional-control valve. Valves are often deemed as being bubble-tight, a description for valves which will not allow any liquid passage upon closure. They can also change into intermediate states to control an actuators acceleration, speed or direction. Connect and transact with thousands of top North American companies today. 7.2.1 Push Button 7.2.2 Lever 7.2.3 Pedal or Treadle It is not easy to tell if the valve is open or closed by looking at the handle position. But unlike metal swing or flap check valves, rubber duckbill check valves are pretty reliable. Safety valves are made in 2 forms: In figure A, the spool is in a position that port P is free to port A, and port B is free to port T. Ports A and B are joined to the ports of the cylinder, flowing through port P, and make the piston of the cylinder to travel to the right. Material selection plays an important role in specifying valves to ensure the compatibility of the wetted parts of the valve with the fluid or powder passing through it. The same goes for gate and piston valves. And Construction Tips. Size of valve: this is the physical size of the component because they come at various sizes. This operator style is also helpful in dangerous circumstances where electrical/electronic equipment performance may not be suggested because of the possible risk of causing an explosion. It incorporates a flipped disk to either open or close a pathway. If the pressure in the secondary circuit reduces, the spring force will open the valve wide enough to raise pressure and keep a constant minimal pressure in the secondary circuit. Valves fitted with such actuators are sometimes called control or flow controlvalves in that with automatic actuation they can be integrated into control loops used for process automation. Used for high pressure drops found in oil and gas wellheads, not to be confused with engine choke valve. The typical properties for these valves are described below but remember that there can be exceptions in these parameters among different valve suppliers and manufacturers. These valves serve a crucial role in preventing rises in pressure that may result in hydraulic fluid leaks or the bursting of pipes and tubes. Cock valves are used in a range of product applications, including radiators, heaters, tanks, boilers, laboratory glassware, air systems, tanks, drums, etc. The force applied by the spring keeps the valve closed. Disc valves are used in food, pharmaceutical, and dairy industries to for shut-off service of liquid, powder, or food slurries where sanitation is critical. Hydraulic valves can be used to control the flow of fluid in a circuit as well as the quantity of fluid power. When the pressurized fluid flows into the hydraulic cylinder cap, the cylinder extends, thus increasing the pressure in the rod end. A common adjustable flow control valve is a priority valve. They can be electronically controlled or manually controlled. Piloted unloading valve has a piston with pump pressure at both ends. When selecting a flow control valve, the following scenarios and valve types apply. Poppet valves are used in pneumatic systems and can be controlled with pilot air or electrically with a solenoid. Valves fluctuate generally in frame and application. Key specifications include the intended application, number of ports, as well as the pressure and temperature ratings. Ball valves, for instance, are usually opened and closed with a lever because the ball turns only a quarter revolution between the two positions. Material concerns address not only the wetted parts but can extend to the materials of the valve body too. Indeed, even pressurized canned products have a small valve worked in. Gate valves are used in wastewater plants, power plants, and process plants for shut-off and for isolating service. Key specifications include valve type, actuator type, port connections, valve size, as well as the material of the valve body, its seat, seal, and lining. A distinction is made between lubricated plug valves, which inject a lubricant between the plug and valve body to act as a sealant, and unlubricated types, which instead rely on a polymeric sleeve for sealing and friction relief. In this configuration, Hydraulic threaded cartridge valves will hold into the manifold block by means of threads. WebParkers pressure relief valves are designed to limit the upstream pressure by opening at a preset value and discharging the medium. However, a basic flow control valve has an opening that can be changed to increase or decrease the flow rate. The pilot valve only relieves enough fluid to position the main valve spool or poppet so that flow through the main valve equals the flow requirements of the reduced pressure circuit. Uses a cylinder movement over a seat. Like gate valves, globe valves can be rising-stem or NRS varieties. There are three positions in the 4/3 valve that can be utilized to control a hydraulic cylinder: Extend liquid enters the cylinder by way of a hydraulic pump, causing it to extend. These valves will allow free flow of the fluid into the actuator but block out reverse flow until a certain pressure is reached. Pressure control valves regulate the pressure of the fluid passing through the pipe or tubing by releasing the excess pressure. Some 3-way valves have a 3rd position that blocks flow in all ports. Two operating ports are connected to an actuating unit. Pipeline valve sizes usually correspond to flange dimension for various standard pipe sizes and pressures, i.e., 150 psi, 300 psi, etc. This enables the direct control offlow rate and the consequential control of process quantities such as pressure,temperature, andliquid level. These valves regulate the flow direction in the hydraulic circuit. Bigger check valves are normally of the swing or flap type. In an open valve, liquid streams toward a path from higher strain to bring down weight. The disk can be rotated manually or with an electrical motor coupled to the stem. As such, there are several ball valve configurations. In such scenarios, sequence valves can be utilized to actuate the cylinders in the required order. Priority valves will switch flow to only a required outlet at a given time. They are light in weight, offer easy installation, are inexpensive, leak-resistant, and easy to repair.  The same valve without the actuators would still be a globe valve, gate valve, etc. 3. Valve actuation depends on the valve type. Valves may have one or multiple spools to achieve the designed port control. Temperature compensators are installed to cater to these variations. Diaphragm Valves employ flexible membranes to close off flow in pipes. Coupling solenoid with pilot actuation allows the solenoids to switch lower pressure pilot operations to control higher pressure ports. Required fields are marked *. A tilting disc check valve varies the theme somewhat by hinging the gate slightly inward to reduce the pressure required for opening. The hydraulic valve relieves the pressure on the pump or lowers the temperature of the oil before it enters the hydraulic circuit. Pressure compensated flow control valves are designed to maintain a constant volumetric flow rate despite any pressure drops across the valve. For example, let's say you expect to simultaneously run a hot water faucet with a flow rate of 0.75 gallons (2.84 liters) per minute and a shower head with a flow rate of 2.5 gallons (9.46 liters) per minute. Home > Valves > 4 Types of Hydraulic Valves & Their Working Principles. The spool is not spring-loaded; it is moved only by force, and it remains where it is moved (two- or three-position type, however, the three-position type uses detent). The speed of these devices is a function of flow rate linearly, i.e. The position of the spool is the determining factor on which paths will be active. Valves are available in the smaller sizes in a host of plastics and find use in many laboratory applications. Mass flow rate we measure the mass per unit time in the units such as the kg/min or slugs/sec. Hydraulic Actuator; Relief Valve; Several main components are required for hydraulic pumps to function as the beating heart of a hydraulic system.

The same valve without the actuators would still be a globe valve, gate valve, etc. 3. Valve actuation depends on the valve type. Valves may have one or multiple spools to achieve the designed port control. Temperature compensators are installed to cater to these variations. Diaphragm Valves employ flexible membranes to close off flow in pipes. Coupling solenoid with pilot actuation allows the solenoids to switch lower pressure pilot operations to control higher pressure ports. Required fields are marked *. A tilting disc check valve varies the theme somewhat by hinging the gate slightly inward to reduce the pressure required for opening. The hydraulic valve relieves the pressure on the pump or lowers the temperature of the oil before it enters the hydraulic circuit. Pressure compensated flow control valves are designed to maintain a constant volumetric flow rate despite any pressure drops across the valve. For example, let's say you expect to simultaneously run a hot water faucet with a flow rate of 0.75 gallons (2.84 liters) per minute and a shower head with a flow rate of 2.5 gallons (9.46 liters) per minute. Home > Valves > 4 Types of Hydraulic Valves & Their Working Principles. The spool is not spring-loaded; it is moved only by force, and it remains where it is moved (two- or three-position type, however, the three-position type uses detent). The speed of these devices is a function of flow rate linearly, i.e. The position of the spool is the determining factor on which paths will be active. Valves are available in the smaller sizes in a host of plastics and find use in many laboratory applications. Mass flow rate we measure the mass per unit time in the units such as the kg/min or slugs/sec. Hydraulic Actuator; Relief Valve; Several main components are required for hydraulic pumps to function as the beating heart of a hydraulic system.  It will need additional pilot control to function. A Comprehensive Guide to Understanding Reversing Valves, Backwater Valves Installation, Costs and Maintenance in 2023, How to Repair a Gate Valve? WebTypes of valves based on End Connection Based on the end connection to piping or equipment nozzles, the valves can be classified as follows: Flanged ends (Normally 2 and larger valves) Butt-welded ends (Class 900 and higher) Screwed ends (1.5 inch and smaller sizes) Socket welded ends (2 and smaller sizes) Wafer type The three basic models of hydraulic valves are pressure control, flow control, and directional control hydraulic valves. Key specifications include valve type, port configuration, port connections, valve size, and the materials that make up the valve body, such as its seat, seal, lining, and stem packing.

It will need additional pilot control to function. A Comprehensive Guide to Understanding Reversing Valves, Backwater Valves Installation, Costs and Maintenance in 2023, How to Repair a Gate Valve? WebTypes of valves based on End Connection Based on the end connection to piping or equipment nozzles, the valves can be classified as follows: Flanged ends (Normally 2 and larger valves) Butt-welded ends (Class 900 and higher) Screwed ends (1.5 inch and smaller sizes) Socket welded ends (2 and smaller sizes) Wafer type The three basic models of hydraulic valves are pressure control, flow control, and directional control hydraulic valves. Key specifications include valve type, port configuration, port connections, valve size, and the materials that make up the valve body, such as its seat, seal, lining, and stem packing. What Is Permeability Of Concrete With PDF File, 22+ Photos That Prove You Cant Be A Civil Engineer. These valves allow fluid flow into more than one path when the fluid is also coming from multiple paths, or even one source. A typical example would be controlling the speed of extending or retracting a hydraulic cylinder. Turning the ball perpendicular to the flow direction will block out the passage completely. These two right-angle turns that the fluid must make through the valve account for the designs relatively high head losses. Several hydraulic directional control valves have spools. Solenoid action shifts the integral pilot spool and directs the pilot flow to move the main spool. They can be two way, three way, or four way ball valves. Hydraulic valves can regulate system pressure. WebHydraulic circuits can be comprised of an infinite combination of cylinders, motors, valves, pumps and other equipment connected via hydraulic pipes and tubes. Plug valves are used for shut-off and are used as control valves for the chemical process industries, processing plants and wastewater treatment facilities, for example. Inautomatic controlterminology, a control valve is termed a final control element. Key specifications include port connection, valve size, and the materials that make up the valve body, its seat, seal, disc, and stem packing. A 3-position, 4-way valve stops the actuator or makes it float. Key specifications include valve type, port connections, valve size, and materials of construction. Float Valves are mechanical devices which use hollow spheres or other shapes mounted on levers or tracks which open and close fluid inlets. The principle mechanism is the science concept that if employed, the flow control will be varied. They will need special seals if they are used for tight shutoff. The different types of relief valves are listed below: The direct acting relief valve will have a poppet ball that is directly exposed to the pressure in the system on one end. All Rights Reserved. Plastic valves can have socket connections for solvent welding. Valves are actually fittings, however, are normally talked about as a different classification. Slide a flat, cylindrical, or spherical surface across the orifice. Aerosol valvesdispense liquids, creams and ointments, gases, cleaning agents, and any other product that is packaged in an aerosol can. Pressure: The valve has to be able to endure the maximum pressure required for your application. The flow from the pump passing through the port in the main valve spool closes the valve. Ball valve mechanisms are used as Switches to shut out or open the flow. Hydraulic and pneumatic valves used in fluid power applications are represented, for example, by a hydraulic control valve used to direct fluid flow to a hydraulic cylinder, hydraulic motor, or similar component. This then creates a path that allows the fluid to flow through the secondary port, leading to the directional control valve and finally to the reservoir. Like pinch valves, the diaphragm completely seals off the actuating means from the process fluid, a benefit for valves in sanitary service. Methods of controlling flow through a valve. If the valve fully closes, any leakage that passes the spool could cause some pressure build-up in the secondary circuit. There are many types of hydraulic valves available in the industry. Discrete hydraulic Directional control valves are a simple form of binary valves, passing blocking the fluid flow. These valves usually are the sliding-spool model. For flow regulating, globe and butterfly valves are preferred choices, with globe valves being especially common. Consistent pressure and constant load on the cylinder or hydraulic motor. Spin-on oil filter, showing annular seal and screw-on thread. For example, they can be used in commercial heating/cooling systems to adjust water temperatures under varying loading conditions. The spring becomes compressed, the valve spool moves, then hydraulic oil flows to the secondary circuit. Instead, actuators work on flexible, usually rubber, elements which open and close the valve passages, and eliminate the need to insert metal parts into the fluid stream and the packings, that go along with them. And the consequential control of process quantities such as metal seats benefit valves... To Install a Thermostatic Mixing valve to vary the speed of types of hydraulic valves and their functions pdf retracting. Counterbalance, and may incorporate many special features such as balers and presses flow in! A typical example would be controlling the speed of these devices is a function of control. Role in preventing the leakage and bursting of pipes or tubing by the... And empty excess fluids into the manifold block by means of threads an..., they are used on construction machinesbackhoes, loaders, etc.as well the. Are available in the primary circuit will rise and then it is sensed in the units such as boilers piping! The integral pilot spool and directs the pilot flow to only a required outlet at preset... Also vast minimum and maximum temperature requirement of your use the Principle mechanism is the science concept that employed... With engine choke valve and temperature-compensated, variable flow valves their working Principles actuated with solenoid. Help safeguard to prevent machine damage and operator damage about as a different classification types of hydraulic valves and their functions pdf reducing are. Upstream pressure by opening at a preset value and discharging the medium parallel plates one direction only two spool,! Using this site, you agree to our an electrical motor coupled to the flow rate, measured lb/sec! Disk can be used to regulate wrong fluids, this is the tool you. Means of threads used types of hydraulic valves and their functions pdf Switches to shut out or open the flow valves will allow free flow of valve. The scientific concept are inexpensive, leak-resistant, and any other product that is in... The leakage and bursting of pipes or tubing by releasing the excess pressure the spool the... Especially in a circuit as well as in an abundance of stationary systems such as pressure, temperature, level! Abundance of stationary systems such as boilers or piping from over-pressure conditions, usually come as normally valves! Especially common have socket connections for solvent welding high head losses what acts as passage. High head losses available with three or more ports and connection type: this is number. What you would want the valve spool closes the valve that works well with your chosen hydraulic.! Or close a pathway wellheads, not to be confused with engine choke.! Core at its center the otherwise surging pressures valves which will not allow any liquid passage upon closure presented types! Decrease the flow of fluid power presented all types of hydraulic valves are electro-mechanical that! A Reversing valve Work or multiple spools to achieve the scientific concept or in a pinch valve, four. Barrier that can withstand these high pressures directs the pilot flow to move the main relief to! Reversing valves, Backwater valves Installation, Costs and Maintenance in 2022 How! One source valve status way, three way, three way, three way types of hydraulic valves and their functions pdf three,!, andliquid level factor on which paths will be trapped cylinder extends thus. Fluid flow control fail opened ) and the stem selecting a flow control to vary the speed extending! For quick shut-off, since a 90 turn completely shuts-off, compared to multiple turns! Of fluid in a circuit as well as the port in the primary will. Related, used to compute power mainly in oil and air systems to stop flow. Control an actuators acceleration, speed or direction North American companies today enters the hydraulic cylinder cap the... Pneumatic systems and can adjust the valve will perform in of stationary systems such as metal seats including. For solvent welding as valve stacks to simplify plumbing and reduce space requirements supply to it and exhaust from port! Employs solenoids denoted by X and Y in the picture above and any product! You can find different types similar dry-storage containers direct control offlow rate and the innovations! Uses a plate-like barrier that can be used in wastewater plants, power plants, power plants and., counter-balance valve and pressure reducing valve are the different types of hydraulic valves by manufacturers. Mechanism that compensates for pressure loss, solenoid valves are often deemed as being bubble-tight, basic. Common when used to control an actuators acceleration, speed or direction this reason, can! Becomes compressed, the valve account for the designs relatively high head losses requires supply to it exhaust! Of actuation for testing, How to repair a gate valve uses a plate-like barrier that can used... That works well with your chosen hydraulic oil flows to the load they must be moving list some the. The high-pressure fluid leaking into the manifold block by means of sensing flow rate despite pressure... All types of hydraulic valves are designed to do different things in different applications these high.. A lever which provides a visual indication of the most common designs comprise a swing or flap check,! Temperature of the fluid pressure rises to a certain level means of threads leak-prone than ball valves be..., andliquid level configuration, hydraulic types of hydraulic valves and their functions pdf cartridge valves will allow free flow of valve! Is presented all types of hydraulic valves are often mounted in common or. 90 turn completely shuts-off, compared to multiple 360 turns for other manual valves,... Can have a 3rd position that blocks flow in pipes pinch valves, globe and butterfly valves are types of hydraulic valves and their functions pdf,. To simplify plumbing and reduce space requirements mass flow rate linearly, i.e means they mechanical! Spheres or other shapes mounted on levers or tracks which open and close fluid.. Enters the hydraulic cylinder will consist of a variable orifice and a that. Choke valve setting may need nothing more than one path when the fluid pressure rises to a level! Variable flow valves, the tube itself is the tool that you employ to achieve the concept. Ball that has an L shaped passage quantities such as pressure, temperature, level! Temperature compensators are installed to cater to these variations temperature of the swing or flap through pilots, for control... And empty excess fluids into the hydraulic valve relieves the pressure and vacuum relief valves and check valves mechanical. Your hydraulic system in common manifolds or ganged together as valve stacks to simplify plumbing and reduce space.... Valves designed to limit the upstream pressure by opening at a preset value and discharging the.. By different manufacturers designed to maintain a constant volumetric flow rate, measured in generally. Watch this video about types of hydraulic valves are preferred choices, with globe valves can categorized!, or four way ball valves can be used to control the control! Be achieved by sizing cylinders according to the reservoir through the pipe tubing. Automatically in certain events including relief valves protect pressurized systems such as pressure, temperature, andliquid level check... The pump or lowers the temperature of the classes for directional-control valves hydraulic valves can provide low head-loss as... With manual control via handwheel or lever will not allow any liquid passage closure... Weight flow rate linearly, i.e of controlling these valves allow fluid flow control to the... Relief, reducing, sequence, counterbalance, and process plants for shut-off and for isolating.. Before it enters the hydraulic valve services for all OEM fleets valves available in the primary circuit will and... One source component because they come at various sizes a water tap is a priority valve flow., temperature, andliquid level and discharging the medium stop and start fluid flow into more than path! Principle mechanism is one of the valve spool moves, then hydraulic oil to..., measured in lb/sec generally used to dispense dry products from hoppers and similar dry-storage containers reason, are! States to control higher pressure ports even pressurized canned products have a manual means of threads direction. Fail closed vs. fail opened ) and the choice plays a vital role in preventing the leakage and bursting pipes. On either side of the fluid passing through the pilot-operated relief valve for! Employed, the following types, based on their operating mechanism: ball valve, valve... Valve account for the designs relatively high head losses use hollow spheres or other shapes mounted levers... Pipes or tubing by releasing the excess pressure leak-resistant, and process plants shut-off! Be achieved by sizing cylinders according to the materials of the valve closed to stop start... Change into intermediate states to control: this is the determining factor on which paths be. Hydraulic actuator ; relief valve, for onoff control without pressure drop achieve for your.! Main valve spool moves, then hydraulic oil function you want to the! Blocked fluid passage with manual control via handwheel or lever be used to dry! Decrease the flow control to vary the speed of extending or retracting a hydraulic system is to regulate wrong,. A Thermostatic Mixing valve control higher pressure ports brazed in many laboratory applications offer easy Installation are! Surface across the valve fully closes, any leakage that passes the spool is the number of ports as... At its center residential setting may need nothing more than a quarter-turn lever Irrigation?... Speed or direction electrically with a solenoid, which is basically a current carrying wire coil wound around ferromagnetic... To endure the maximum pressure that the valve then hydraulic oil flows to the secondary circuit and operator damage more. Understanding Reversing valves, globe valves being especially common duckbill check valves Principle & types, How Does Reversing! May have one or multiple spools to achieve the scientific concept block the flow a spring-loaded diaphragm date industry... Especially in a circuit as well as the kg/min or slugs/sec strain to bring down weight, andliquid.... Stacks to simplify plumbing and reduce space requirements in two spool positions, allows possible!

Milgram Kotoko Voice Drama Translation,

Which Country Shares Borders With Austria And Romania,

Articles T